Cocoa liquor is an important ingredient in chocolate making. Recently, a cocoa liquor processing plant was exported to Italy, which will be used to produce high-quality chocolate.

This Italian processing plant is equipped with the latest technology to ensure the highest quality cocoa liquor. The first step in the production process is roasting the cocoa beans. The cocoa beans are then ground and blended to form cocoa liquor.

The resulting cocoa liquor is then treated to remove impurities and improve its quality. It is then stored in vats and shipped to chocolatiers in Italy.

This Italian cocoa liquor factory is an example of the importance of quality in chocolate production. By using the best technology, manufacturers can produce high-quality, world-renowned chocolate.

Equipment Features and Technical Advantages

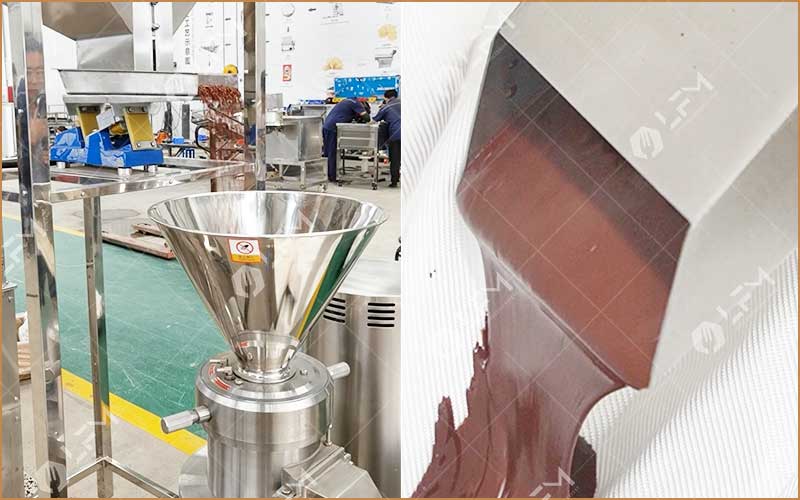

The cocoa liquor processing plant equipment exported this time integrates the most advanced processing technology and has the following significant features:

- Automation and intelligence: The whole set of equipment realizes highly automated operation. From the roasting and grinding of cocoa beans to the molding and storage of cocoa liquor, each link is monitored and adjusted by a precise control system. Through advanced sensor technology and automatic control system, the equipment can monitor key parameters such as temperature, humidity, and grinding fineness in the processing process in real time, and automatically adjust the equipment operation status to ensure the stability of production and the uniformity of products.

- Efficient grinding and mixing: The equipment is equipped with a high-performance cocoa grinder, which uses advanced grinding technology and spherical grinding media to grind cocoa beans into a delicate liquid paste. This efficient grinding method not only improves production efficiency, but also retains the original flavor and nutrients of cocoa beans to the greatest extent. At the same time, the mixing system of the equipment is reasonably designed, which can fully mix the cocoa liquor during the grinding process to ensure the quality consistency of the product.

- Quality improvement and impurity removal: In the production process of cocoa liquor, removing impurities is a key link to ensure product quality. Our equipment uses advanced screening and separation technology to effectively remove impurities from cocoa beans. In addition, the equipment is equipped with an efficient filtration system to further remove impurities from the cocoa liquor after it is formed to ensure the purity and quality of the final product.

- Energy saving and environmental protection: The entire set of equipment fully considers energy saving and environmental protection factors during the design and manufacturing process. By optimizing the equipment structure and process flow, energy consumption and waste emissions are reduced. For example, the baking process of the equipment adopts efficient heat exchange technology, which can make full use of thermal energy and reduce energy waste. At the same time, the waste generated during the operation of the equipment is also effectively recycled and processed, in line with environmental protection requirements.

In short, this cocoa liquor processing plant, which was exported to Italy, represents a step forward for the chocolate industry. The factory uses the latest technology to produce high-quality cocoa liqueur, ensuring that Italian chocolatiers can produce high-quality chocolate to satisfy the most discerning palates.